Foldable Garbage Trash Bin Making Machine

The outdoor plastic garbage bin making machine uses HDPE raw material with high impact strength to make large outdoor sorting garbage bins by injection molding principle. A plastic trash bin can be produced in a few minutes using a plastic garbage bin mold, and the production speed is fast. The trash can made of high-strength material is hard and stable, not easy to deform, and has the characteristics of acid resistance, alkali resistance, and easy cleaning. And YG plastic injection molding machine manufacturer provides various specifications for trash bin molds. Other injection molding machines include plastic chair making machines, plastic toy manufacturing machines, cargo pallet making machines, etc. Please contact us to get the garbage can making machine and trash bin molds price.

Finished Plastic Garbage Bin Display

Trash Bin Injection Molding Process

Plastic Trash Can Making Machine Parameters

| Number | Capacity(L) | Size(MM) | Weight(KG) | Roller(KG) | Barrel(KG) | Lid(KG) | Total Weight(KG) |

| 1 | 100 | 480*530*790 | 2.6 | 1.2 | 4.55 | 0.71 | 9.06 |

| 2 | 120 | 530*475*925 | 2.6 | 1.2 | 5.7 | 0.73 | 10.23 |

| 3 | 240 | 725*585*1020 | 2.6 | 1.5 | 9.34 | 1.62 | 15.06 |

| 4 | 240 | 735*590*1070 | 2.6 | 1.5 | 9.5 | 1.53 | 15.13 |

| 5 | 360 | 705*845*1110 | 2.6 | 1.8 | 15.8 | 2 | 22.2 |

| 6 | 660 | 1285*775*1295 | 12 | 26.15 | 6.6 | 44.75 | |

| 7 | 1100 | 1060*1200*1295 | 12 | 29.4 | 6.85 | 48.25 |

The above are the specifications and machine models of trash cans made by trash bin making machines. You can choose the appropriate model according to the specifications of the trash can that you need to make. Usually, the size of the trash can hanging on the sanitation vehicle is 240L. In addition, YG garbage bin injection molding manufacturer can also customize according to customers’ needs.

Features Of Plastic Garbage Bin Injection Molding Machine

Precision

Adopts The high rigidity box-type template, and the computer simulation optimization technology is introduced to make the clamping mechanism run smoothly, and quickly, with high strength and good rigidity. Equipped with high-precision, high-performance rotary encoder, and pressure sensor to monitor and feedback flow and pressure respectively.

Energy Saving

Fully digital closed-loop control, using permanent magnet synchronous servo click and dedicated servo driver. The output power varies with the load, and there is no waste of excess energy.

Efficient

Plastic garbage bin making machine adopts special controller, man-machine operation interface, and imported brand for key parts, which is efficient and stable. The drive system of the servo energy-saving injection molding machine responds quickly and quickly, thereby shortening the molding cycle and greatly improving production efficiency.

Good Shape

It is made of 100% high-density HDPE raw material injection molding, which is strong and durable and can effectively prevent the corrosion of weak acids and weak alkalis. The plastic barrels produced are smooth and clean inside, easy to clean, and the barrels can be stacked on each other, which is convenient for transportation and saves space.

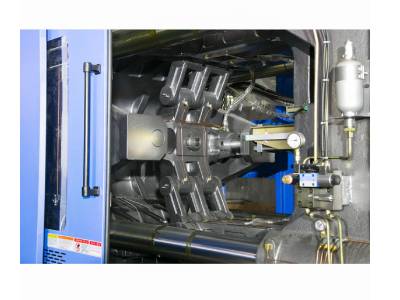

Outdoor Plastic Trash Bin Injection Molding Machine Details

About YG Plastic Garbage Bin Making Machine Manufacturer

YG Plastic Trash Can Making Machine Manufacturer is a manufacturer specializing in the mechanical manufacturing and R&D of plastic products. We provide research and development, manufacturing and sales of various plastic products. Such as plastic bottle making machines, plastic bag making machines, PE plastic machinery, injection molding machine, plastic container making machine, plastic recycling machinery, and other plastic machinery. In addition, YG also provides a variety of plastic molds that have been customized. If you would like to inquire about plastic processing machines, please contact us.

More information:https://www.ygplasticmachinery.com/garbage-trash-bin-making-machine/